The slag pot experts

GVA Krefeld, also known in our industry for decades as “The Slagpot Company”, is more than just a name in the industry. GVA Krefeld has established itself as a global synonym for excellence and expertise in the field of slagpot technology. This well-earned reputation is the result of intensive research, development and innovation that has put GVA Krefeld at the forefront of its field.

For more than 35 years, the GVA design philosophy of our company founder has pursued the goal of extending the service life of slag pots in the economic interest of our customers.

Material

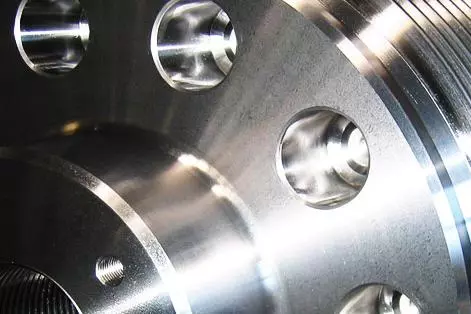

The modern slag pot material is cast steel and has largely replaced the classic cast iron material. Based on the experience of the last 35 years, cast steel with a low carbon content and increased manganese content has proven to be the best. GVA Krefeld has tested a special mixing ratio for this purpose (GVA special cast steel). This material has similar mechanical properties to a G17Mn5 according to EN 10293, for example.

In the past, there was a temporary trend away from cast steel towards nodular graphite cast iron (spheroidal graphite cast iron) because the cost price was lower. Here too, GVA Krefeld uses an optimized spheroidal graphite cast iron material (GVA special spheroidal graphite cast iron). Our trained employees will be happy to support and advise you in selecting the optimum material for your individual requirements.

In order to maintain and extend the life cycle of the slag pots used, GVA Krefeld creates individual concepts for the maintenance, servicing and operation of the pots. GVA Krefeld supports its customers and partners in the optimal use and handling of the slag pot. GVA Krefeld produces operating instructions for the GVA slag pots.

Customer-specific requirements

The task of collecting liquid slag in a predetermined quantity, transporting it from one place to another and emptying it there sounds very simple at first. In most cases, however, the space for providing and transporting the slag buckets is too small and the route to the stockpile is too narrow, winding and/or simply too far away. These problems can usually be overcome with special slag transporters, special equipment or even conversions.

However, due to the complexity of the possible challenges, there are no standard pots and every pot user therefore needs their own customized equipment. GVA Krefeld constructs individually tailored slag pots from the basic specifications of the smelter and the vehicle manufacturer.

GVA after-sales service

After successful delivery, we support our customers in all aspects of slag pot application.

Together with the users, we analyze optimization potentials and develop recommendations to achieve a reduction in repair costs and premature new investments through improved operating conditions.

Why GVA Krefeld?

GVA Krefeld is more than just a manufacturer of slag pots - we are a trusted partner for companies all over the world. With an impressive blend of technical expertise, commitment to quality and customer service. GVA Krefeld is able to deliver customized solutions that exceed expectations.

As the possible in-house requirements are so varied and each user has new special features, the information described here can only provide the most important basic facts. In any case, it makes sense to maintain constant contact between the user and the pot supplier in order to reduce the total pot costs in relation to what is feasible in the long term.

Do you recognize yourself in these challenges? Then please contact us!