Engineering

Design and development are the core of the GVA 'DNA'. Our product development starts with a detailed analysis of the customers requirements. The result leads to the development of the design, the construction and corresponding simulation, the prototype as scale-model. After this process has been successful, manufacturing starts.

Dimensions, free space and tolerances, any customer-specific process (application area, -goals and -time, material, the environmental standards, the areal / workshop conditions, the weather). Every product is individually customized.

Design

Engineering and design are both in the center of our development process. The corresponding results of the problem analysis predefine the optimal layout of our future product.

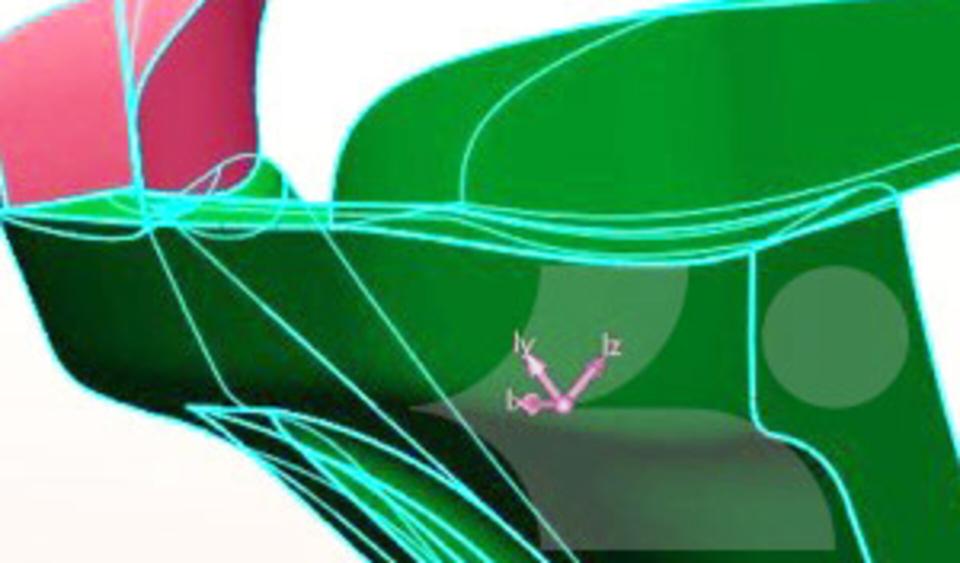

The process sets system boundaries and interoperating areas paired with thermodynamic properties and geometric shapes leading to the required framework for the construction.

Your product is not performing as expected? This can often be managed by simple changes or optimizing the construction.

The GVA engineering and design process is the link between the voiced problem and the solution, between starting point and construction, between requirement and final product.

Technology

Casting metal is an old tradition and craftsmanship! Already within the design and engineering phase GVA refines and defines the casting technology. The use and assistance of 'high-tech' at GVA is essential. By using 3D-CAD, rapid prototyping and simulation tools for design, engineering and casting system, GVA can identify product and production flaws at an early stage and improve the desired properties and parameters.

Our self-developed procedures adopted in our casting technology create cost efficient products for our clients at a highest possible quality level.

Because of our technology procedure, distinctive material knowledge and most modern production process GVA products are premium and intelligent casting, forging and fabricated products on the market.

Areas of business

GVA specializes in cast, forged and welded products. We implement optimal solutions evaluating and understanding the customers' actual requirement and performance requests.

-

Components for presses

Components for steel plants

Components for cylinders

Housings

Rolls

Roll stands

Bearings races and gear wheels

-

Castings for the buildings and foundations

Glass holder

Sheet pilings and sheet clamps

-

Segments and grinding bowls

Segments and grinding bowls

Grate, grate plates and furnace segments

Drive shafts and gear wheels

Laufringe, Zahnräder

-

Slag pots

Drop balls

Welding constructions

Welding constructions

-

Drive shafts

Ship parts

Yokes and gear housings

Armature windings

Bollards

Anchorages for sheet pilings

Cleats, thimbles and shackles

-

Slag pots, ladles and scrap baskets

Spare parts for the melt shop

Converter components

Vacuum covers

Sinter cars, grate bars

Wear plates, furnace grates and other wear parts

Roll chocks, rolls, frames and other spare parts

Sampling spoons

Beams and crane hooks

Springs for coke oven doors or similar

Insulation and heat protection in oxide-ceramic

Quality

The GVA process starting with the analysis of design and production up to the quality assurance. Every product is evaluated in the inquiry phase considering feasibility, faultless production and quality standards.

Feasibility analyses are supported by computer-aided methods such as finite elements (FEA) or solidification simulations. These provide further conclusions on design and production.

Results from simulations are continuously re-evaluated, starting with their first operation, and designs are developed further. These results are also included into our quality assurance and inspection of all products.

Know how

The intense cooperation between GVA employees and engineers and technicians of our clients results in a creative and highly professional working atmosphere, having a positive impact on the performance and quality of our products.

One key component to this success is the continuous education and training of GVA’s employees within the specialist’s field.

Detailed documentation of developments and lab results are the foundation of a solid base for a feasible framework of efficient and risk-free new products.

-

Slag operation in melt shops

-

Foundry technology

-

Casting technology

-

Ingot molds for steel plants

-

Castings for architectural components

-

Mechanical engineering

-

Plant engineering

-

Shipbuilding and water engineering

Special Products

GVA Krefeld has specialized in specific products and has built up an extended core competence. The following products implement GVA’s expertise in the areas of design, simulation, choice of material, mold technology, casting technology, hardening and tempering. These are so called GVA products:

- Ingot molds

- Crushing balls

- Rolls

- Drill pipe

- Crushing machines

- Slagpots

- Chutes

- Ladles

Based on our experience in regards to these products, we often develop complete new concepts around the application. Part of this system is GVA’s “continuous improvement process” – a process to implement permanent adjustments and developments in every step of the production process.